Precision Plastic

Manufacturing Solutions

Custom Injection Molds & Plastic Parts for Smart Products, Consumer Goods & Industrial Applications

TENGJIN MFG delivers specialized manufacturing solutions with 20+ years of core expertise in custom injection molds and plastic parts. From smart devices to industrial components, our precision engineering helps your products excel in competitive global markets.

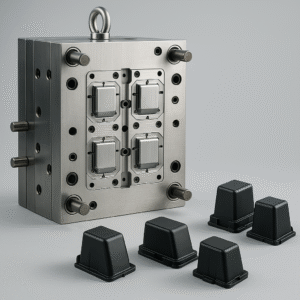

Custom Injection Molds

Precision engineered tooling

Quality Assurance

Following ISO 9001:2015 standards

20+ Years Experience

Core manufacturing expertise

Engineering Support

DFM & Technical Consultation

From Design to Reality

See how we transform digital designs into precision-manufactured products

3D CAD to Reality

Mold Engineering Excellence

From Prototype to Production

Industry-Specific Solutions

With 20+ years of precision mold making experience, we provide customized solutions across different industries with professional engineering support.

Smart Innovation

Specialized in high-precision mold manufacturing for smart devices, ensuring excellent fit and finish for your innovative products.

What we offer

Professional smart device mold manufacturing and plastic parts customization, helping bring your innovative ideas to life.

Why choose us

20+ years of precision mold making experience with advanced equipment and professional engineering support.

Advanced Material Solutions

Unlock unlimited possibilities with our comprehensive material portfolio

With 200+ material grades in our portfolio, we help you select the perfect material for your specific application requirements — balancing performance, cost, and regulatory compliance.

Engineering Plastics

High-performance technical materials for demanding applications

Engineering Plastics

Structural components, high-temp applications, and mechanical parts

Commodity Plastics

Cost-effective materials for high-volume production needs

Commodity Plastics

Consumer products, packaging, and cost-sensitive applications

Elastomers

Flexible materials with excellent recovery properties

Elastomers

Seals, gaskets, grips, and medical applications

Material Compliance

Meeting global regulatory standards and requirements

Global Compliance

Full documentation and traceability for all regulatory needs

Custom Manufacturing Process

Professional & Efficient Manufacturing Journey

Expert Design Review

Our engineering team provides comprehensive Design for Manufacturing (DFM) analysis within 24 hours. We optimize your design for manufacturing efficiency, identify potential issues, and recommend solutions to reduce costs and improve quality.

Expert DFM analysis with 24-hour turnaround time

Cost reduction opportunities identification

Material selection consultation and recommendations

Trusted by Industry Leaders Worldwide

From innovative startups to established manufacturers, our partners trust us to deliver excellence

"TENGJIN's proactive DFM support was a game-changer for us. Their speed and expertise helped us launch our product a full quarter ahead of schedule. They are a true engineering partner."

"For years, TENGJIN has been our most reliable supplier. The quality consistency is exceptional, batch after batch. They truly understand the high standards of the German market."

"The precision of the components we received for our automation line was outstanding. Their team has the technical depth to handle challenging engineering-grade materials and complex geometries."

Success in Action: Featured Case Studies

We don't just make parts; we build partnerships. See how we've helped global leaders overcome their toughest manufacturing challenges.

Rapid Prototyping & Precision Molding

High-Volume Production Excellence

High-Performance Industrial Parts

Our Quality Control Process

At TENGJIN MFG, we implement a comprehensive quality management system ensuring precision, consistency and reliability in every product we manufacture.

Design & Planning Excellence

Our quality journey begins with meticulous planning and design review. By integrating quality considerations from the very start, we establish a solid foundation for manufacturing excellence, identifying potential challenges before they become issues.

Quality Planning

Detailed quality control plans for each project with clear acceptance criteria.

FMEA Analysis

Failure Mode and Effects Analysis to identify and address potential quality risks.

Process Mapping

Detailed workflow analysis to identify critical control points for quality assurance.

We're Not Just a Supplier, We're Your Engineering Partner

Beyond manufacturing excellence, we bring 20 years of engineering expertise to collaborate with you from concept to completion.

Ready to Turn Your Design into a Tangible Success?

Whether you have a detailed CAD file or are still refining your concept, our team is ready to help. Choose the path that best suits your current needs.

Get a Free DFM & Project Review

This is more than a quote. Upload your design, and our senior engineers will provide a complimentary review within 48 hours. We'll help you:

- Identify potential manufacturing risks

- Suggest optimizations for material, cost, and function

- Confirm the feasibility of your most critical tolerances

- Provide a preliminary project roadmap

Who is this for: Ideal for R&D teams, engineers, and product innovators looking for an expert technical partner.

Request a Formal Quote

Have your specifications ready? Upload your 2D/3D files, and our team will deliver a detailed and transparent quote, typically within 24 hours. Your quote will include:

- Mold Cost (with mold steel details)

- Unit Price (with volume tiers)

- Material Options & Lead Times

- Clear Payment & Shipping Terms

Who is this for: Perfect for procurement managers and buyers who need a fast, comprehensive, and competitive quotation for a defined project.

Just have a quick question? Or not ready to submit a project?

Email our engineering team directly at [email protected]